Dallas keeps growing. New warehouses rise near DFW Airport. Big distribution centers spread across Lewisville, Fort Worth, and other parts of the metroplex. Developers move fast because demand stays high. However, before steel frames go up and trucks roll in, one thing decides if a project will succeed or struggle: The ground beneath it. That’s where geotechnical engineering comes in. And right now, it plays a bigger role than ever before.

Dallas Is Building Fast — But the Soil Doesn’t Always Cooperate

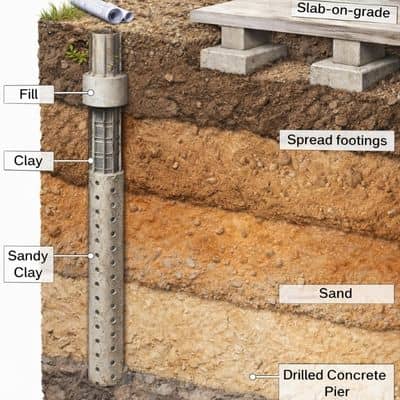

North Texas sits on expansive clay soils. These soils swell when wet and shrink when dry. As a result, foundations can move if builders don’t prepare the site the right way.

Now think about industrial projects. These buildings are not small homes. They carry heavy steel, thick concrete slabs, and constant truck traffic. In addition, many sites include large parking lots and loading docks that take daily pounding from 18-wheelers.

If the soil shifts, everything above it suffers.

Because Dallas continues to attract logistics hubs and warehouses, developers often rush to meet deadlines. However, when projects move quickly without careful soil testing, costs rise later. Cracked slabs, uneven floors, and broken pavement create serious problems.

So, while cranes and crews grab attention, geotechnical engineering quietly protects the investment.

What Geotechnical Engineering Actually Does

Many developers hear the term but don’t always understand what it means.

First, engineers drill borings into the ground. These borings show what lies under the surface — clay, sand, rock, groundwater, or fill dirt. Next, engineers test those samples in a lab. They measure strength, moisture, and how the soil reacts under pressure.

Then comes the most important part.

Engineers study the results and give foundation advice. Should the building use spread footings? Drilled piers? A thick slab? Each choice affects cost and long-term strength.

In addition, geotechnical engineering teams may suggest ways to improve the soil. For example, they may recommend lime treatment to strengthen clay. They may also suggest deeper support in weak areas.

As a result, the whole design team works with real data instead of guessing.

Why Industrial Developers in Dallas Can’t Skip This Step

Dallas industrial land often looks flat. However, flat land does not mean strong soil.

Without proper soil testing, developers risk:

- Cracked concrete floors

- Uneven foundation movement

- Broken pavement in truck yards

- Drainage problems after heavy rain

Moreover, surprise soil issues during construction cause delays. Crews may find weak clay or bad fill that needs removal. That means extra work. Extra work means extra cost.

On the other hand, early geotechnical engineering reduces surprises. Developers can plan soil fixes before construction starts. Because of that, budgets stay more accurate.

In a busy market like Dallas, that matters a lot.

How Geotechnical Engineering Protects Long-Term Value

Industrial projects must last for years. Tenants expect smooth floors for forklifts. Owners expect low repair costs. Buyers expect strong buildings.

Strong foundations start with strong soil.

For example, pavement design depends on soil strength. If engineers ignore weak soil, truck traffic will damage the surface quickly. However, when geotechnical engineering guides the design, pavement lasts longer.

Rain also plays a big role. North Texas storms can bring heavy rain fast. Poor soil and weak drainage can lead to erosion or water problems.

Therefore, geotechnical engineering protects more than just the building. It protects the entire property over time.

Supporting the Whole Project Team

Industrial development takes teamwork. Civil engineers design grading and utilities. Structural engineers design the building frame. Construction managers handle schedules and materials.

However, all of them depend on soil information.

Without good soil data, designers guess. Guessing leads to risk. Because of that, geotechnical engineering supports every other part of the project.

In Dallas, where industrial sites can cover many acres, this support becomes even more important.

Why This Matters During Dallas’ Growth

The Dallas-Fort Worth area ranks among the fastest-growing industrial markets in the country. E-commerce and transportation demand keep driving new projects.

As land near DFW fills up, developers move into new areas. However, soil conditions can change from one site to another. A site in Lewisville may behave very differently than one in South Dallas or Mesquite.

Some properties also contain old fill dirt from past uses. Others sit near flood areas or drainage paths. Each condition requires careful study.

Because projects move fast in a hot market, skipping soil testing may seem like a way to save time. Yet that shortcut often leads to bigger costs later.

Smart developers know that geotechnical engineering is not a delay — it is protection.

What Developers Should Think About Before Building

If you plan to build, ask simple questions:

Has a soil study been done for this exact site? Were borings placed inside the building area? Did engineers study truck loads for pavement design? Did the report include soil improvement steps?

If the answers are unclear, it may be time to review.

Taking this step early can save money later.

The Bottom Line

Dallas keeps expanding. Warehouses rise quickly. Industrial parks grow across the metroplex. However, success does not begin with steel. It begins with soil.

Geotechnical engineering shapes every major industrial project in the region. It lowers risk. It protects budgets. It strengthens foundations. Most of all, it supports long-term performance.

In a fast market, speed feels exciting. Yet strong projects come from careful planning.

Before the next industrial project breaks ground in Dallas, remember this:

The smartest investment isn’t what you build above ground. It’s understanding what lies beneath it.